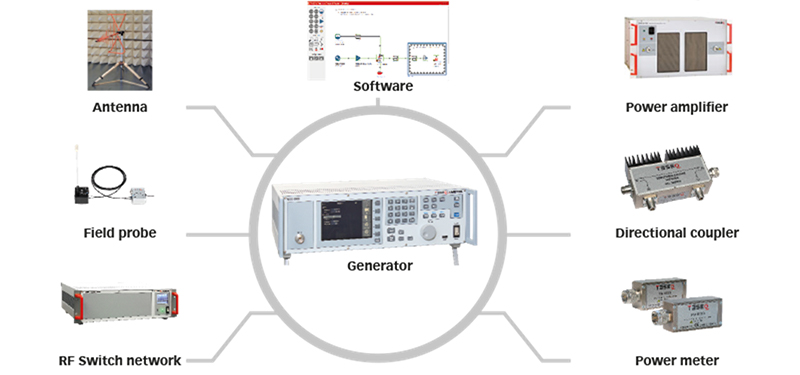

Testing in absorber rooms

The requirement is to generate a homogeneous RF field into which the equipment under test (EUT) is placed to determine if the EUT continues to function correctly. To protect the environment, these tests are carried out in shielded rooms. To achieve field homogeneity, reflections from the walls, ceiling and floor are almost completely suppressed using absorbers. The dimensions of the EUT, antenna distance and absorber size ultimately determine the size of the room.

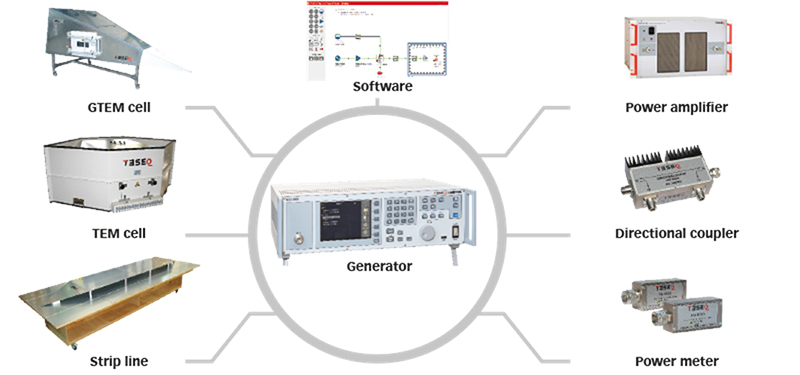

Testing in wave guides (TEM cells, GTEM cells, strip lines)

TEM cells allow the tests to be carried out in the smallest of spaces without disturbing the environment or requiring additional measures. Strip lines, on the other hand, have become established in the automotive industry for coupling the RF fields on cable harnesses. High field strengths can be generated quite efficiently.

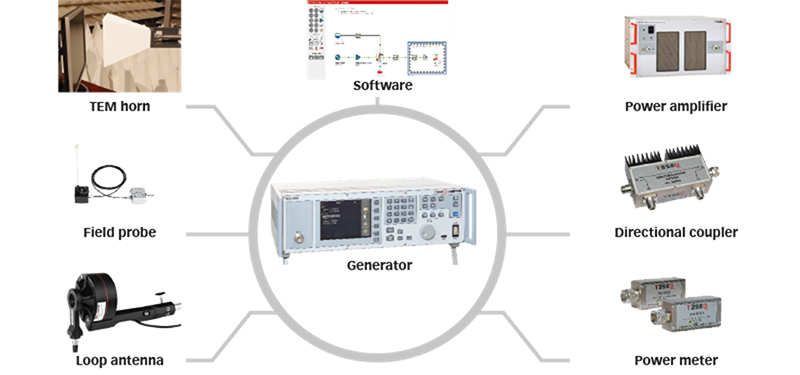

Fields in close proximity

The standard IEC 61000-4-39 "Testing and measurement techniques - Radiated fields in close proximity - Immunity test” defines in addition to existing normative requirements, the immunity to the influence of portable devices with transmitting function. In the range 9 kHz to 26 MHz, the EUTs are scanned with a magnetic field at a distance of 5 cm. Above 380 MHz and up to 6 GHz, the RF field is generated at a distance of 10 cm using a TEM horn.